Digital training for the industry is a necessary part of factory life. Workers must learn how to execute and supervise assembly operations and reconfiguration actions.

New and inexperienced workers must first learn the sequence of actions for each operation. This training takes time and resources and occupies a worker (and a supervisor) who could provide useful support to the production. Besides, even experienced workers will need re-training when a new product enters production or new reconfiguration actions appear in the process.

The rigid form of training that currently takes place in industry undermines attempts at system reconfigurability and costs resources that companies could use better in other areas.

Why resorting to digital training for the industry?

We are currently coming up with digital training to counteract the rigid form of training that takes place in the industry today. This is why instructions are provided as real-time guidelines to the operators while they are performing their actions.

In practice, they consist of visual aids such as:

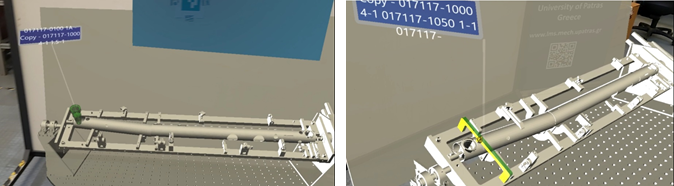

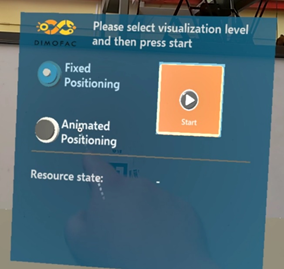

- 3D digital representations of parts that must be assembled to form a product, and the way they have to be placed in the assembly.

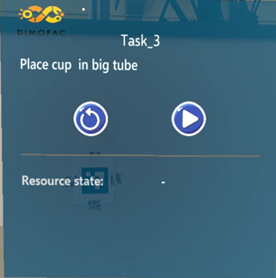

- Written text notifications describing the current action the operators must take.

Wearable devices such as augmented reality glasses or tablets, or even projectors deliver digital instructions to the operator. This way, even inexperienced or untrained workers can complete their operations. Each action they must undertake is being shown in real-time.

In DIMOFAC, we will use digital training for assembly operations as well as reconfiguration instructions when an operator needs to intervene immediately to solve an error in execution (workers can be warned thanks to proactive production line monitoring). DIMOFAC will develop several other capabilities using the same developments used for digital training.

DIMOFAC will be using the HoloLens 2 Augmented Reality glasses as an instructions device. Together with the visualisation part, a digital GUI (Graphical User Interface) is also developed to:

- Provide the task description to the operator.

- Give them the ability to move from action to action and inform the system that they do so.

- Provide them with information about other parts of the industrial execution, such as the status of the other resources (robots, machines, etc.).

The benefits of digital instructions

- Enabling inexperienced workers to easily learn new operations while providing useful results.

- Reducing the cost in money and time for companies to train new workers.

- Reducing the cost in money and time for companies to re-train their workers for new products.

- Enabling the easy reconfiguration of lines.

- Enabling easy and real-time reconfiguration of modules in case of errors.

- Providing several other capabilities, such as malfunction and safety alerts.

- Enabling the communication of the operator with the greater digital architecture of the industrial system.

Article from Angelos Bavelos, Laboratory for Manufacturing Systems and Automation